- All production lines are be made of individual smart cells.

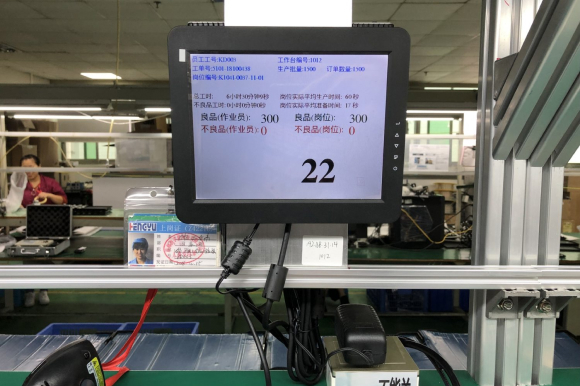

- Each cell is equipped with barcode scanner and all- in-one smart terminal.

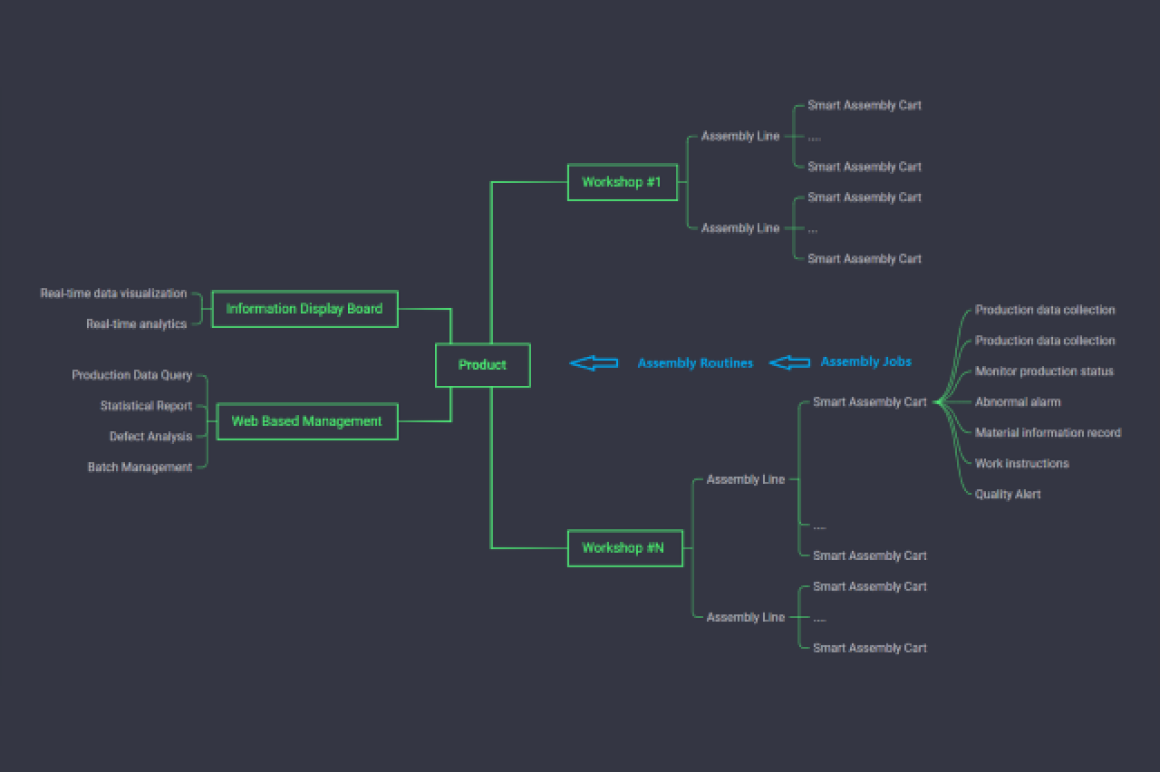

- Each product full assembly is divided into several assembly routines. Each assembly order is composed of several assembly jobs. Under the system, each job will be assigned a unique job ID. Concept: Jobs > Routines > Product

- The smart terminal shows the assembly video of each job. It will also instruct the worker to do all the necessary testing and input the testing result. This can ensure the worker will not miss some working instructions and also ensure the data input is correct.

Smart Factory

- For testing station, the related testing software will be downloaded to the smart terminal automatically when the worker starts the testing job.

- All the technical documents and engineering changes on the product will be promptly downloaded to the smart production line when they are confirmed to be executed. This can ensure the workers will always follow the updated documents to assemble the products.

- Each production cell allows the worker to scan in all the batch numbers of the product materials they are using to assemble the product.

- This can allow us to trace the products produced when one part of the material is later found to have potential problem and needs to be called back.

+852 2394 1852

hy_sales@hengyu-tech.com