Production Management

- Material operations - The PMC distributes the material picking list based on the work order generated by the ERP , and the material picking personnel uses the tablet to pick up the materials.

- Job creation - The production line leader creates a job on the server and inputs the job content, precautions, operation tips (with photos), potential quality concern, etc.

- Process creation - The production line leader creates a process on the server and inputs all the related to the process on a sequential order. He can also create a new process based on a similar process created before and update the jobs on the process.

- Quick job creation - You can use your tablet or mobile phone to quickly create a job, and then use online supplementary job information to complete the information for each job.

Material Management

- Workers at each station need to scan the material barcode and load the material batch information before obtaining the materials and starting work. The system automatically associates the materials with the serial numbers of the products (on the assemble tray) to be assembled, ensuring that every product leaving the factory have clear trace records for all materials assembled in the product.

Process Management

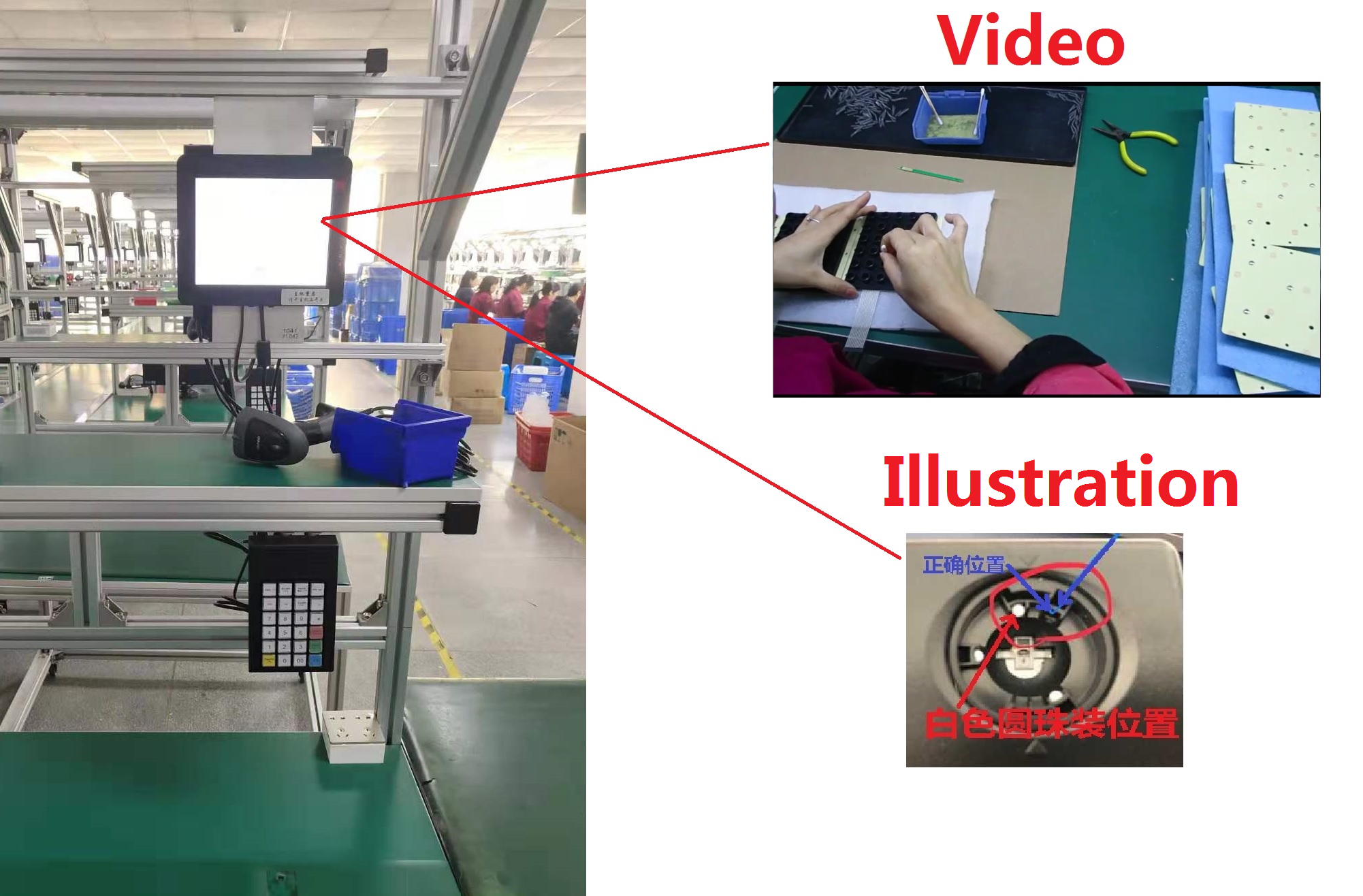

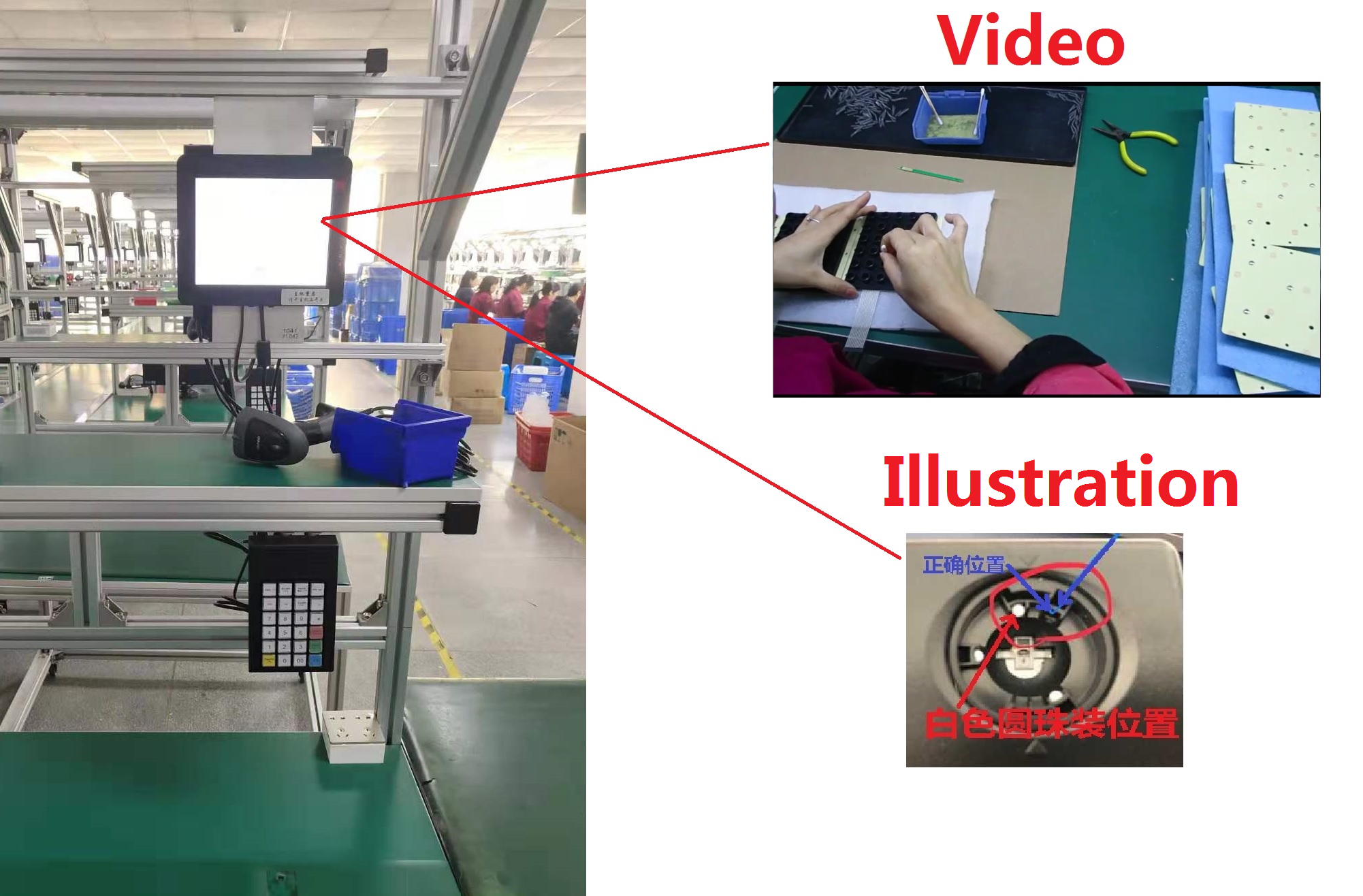

- Production training - After a worker is allocated to a job station, the database will check his/her training information. For worker who is working in the job station for the first time, the smart terminal screen in front of the workstation will compulsorily play the job assemble video before he/she can proceed with the production process.

-

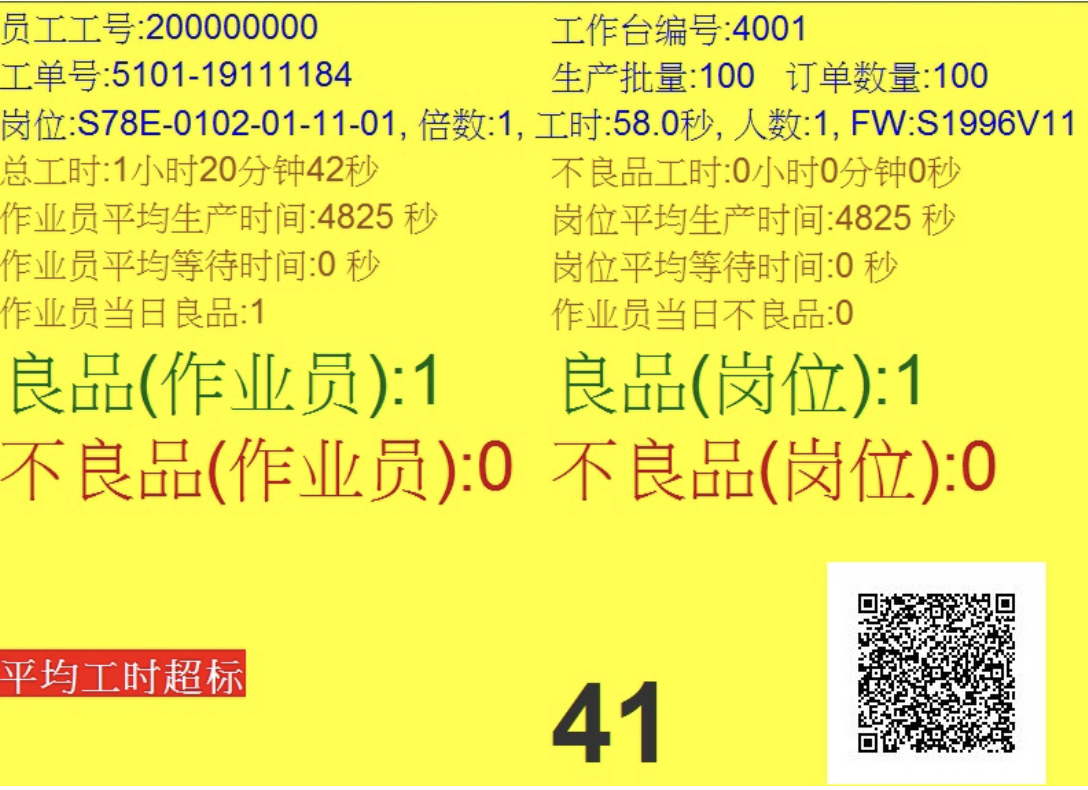

Job station working instructions and performance control - The smart terminal screen can display information such as accumulated working time, good product count, defective product count, etc., and play job assemble video, job precaution photos and quality requirements repeatedly. After the worker finishes a job, he presses the button to count, or the smart tray automatically senses the job completion and add count automatically.

-

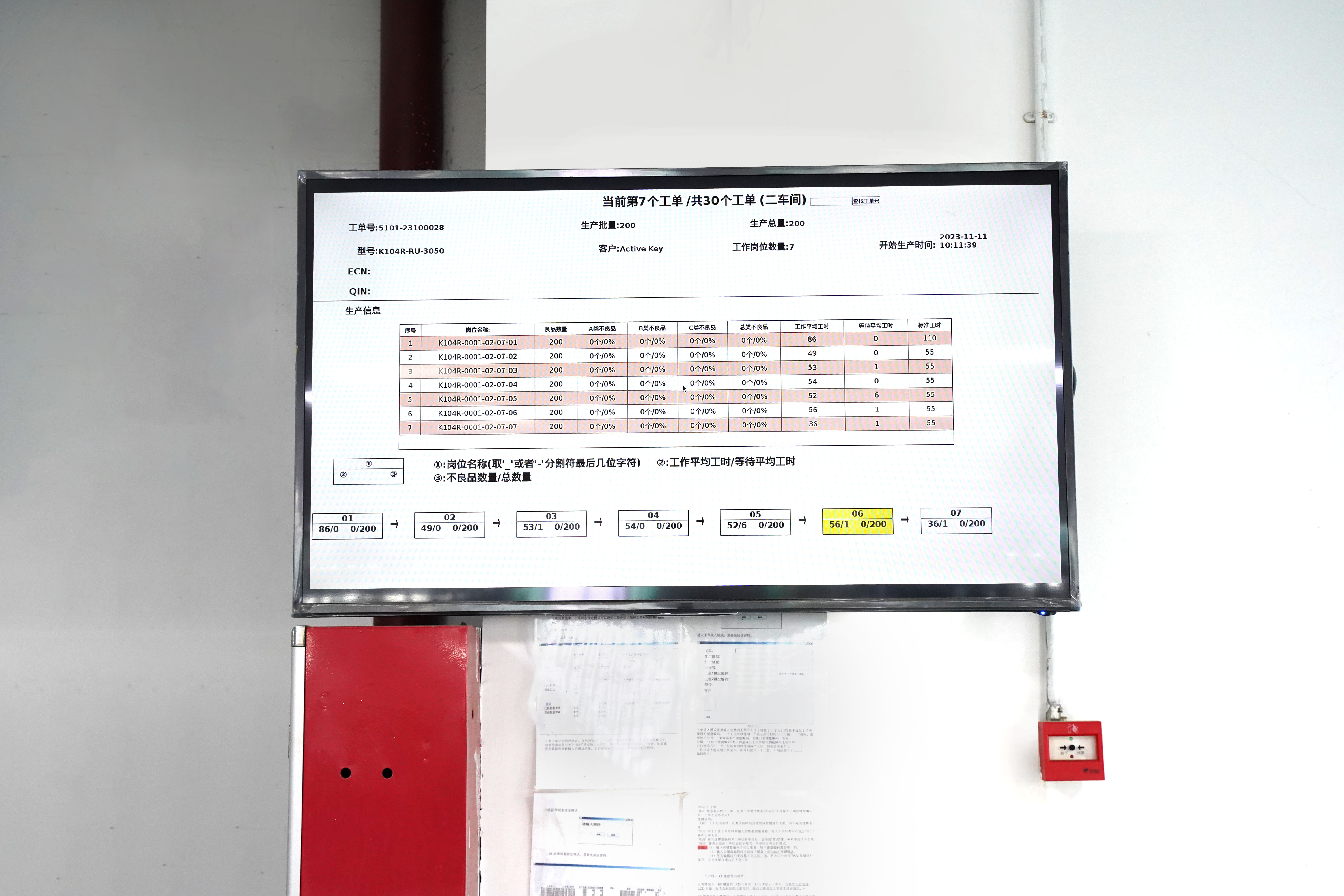

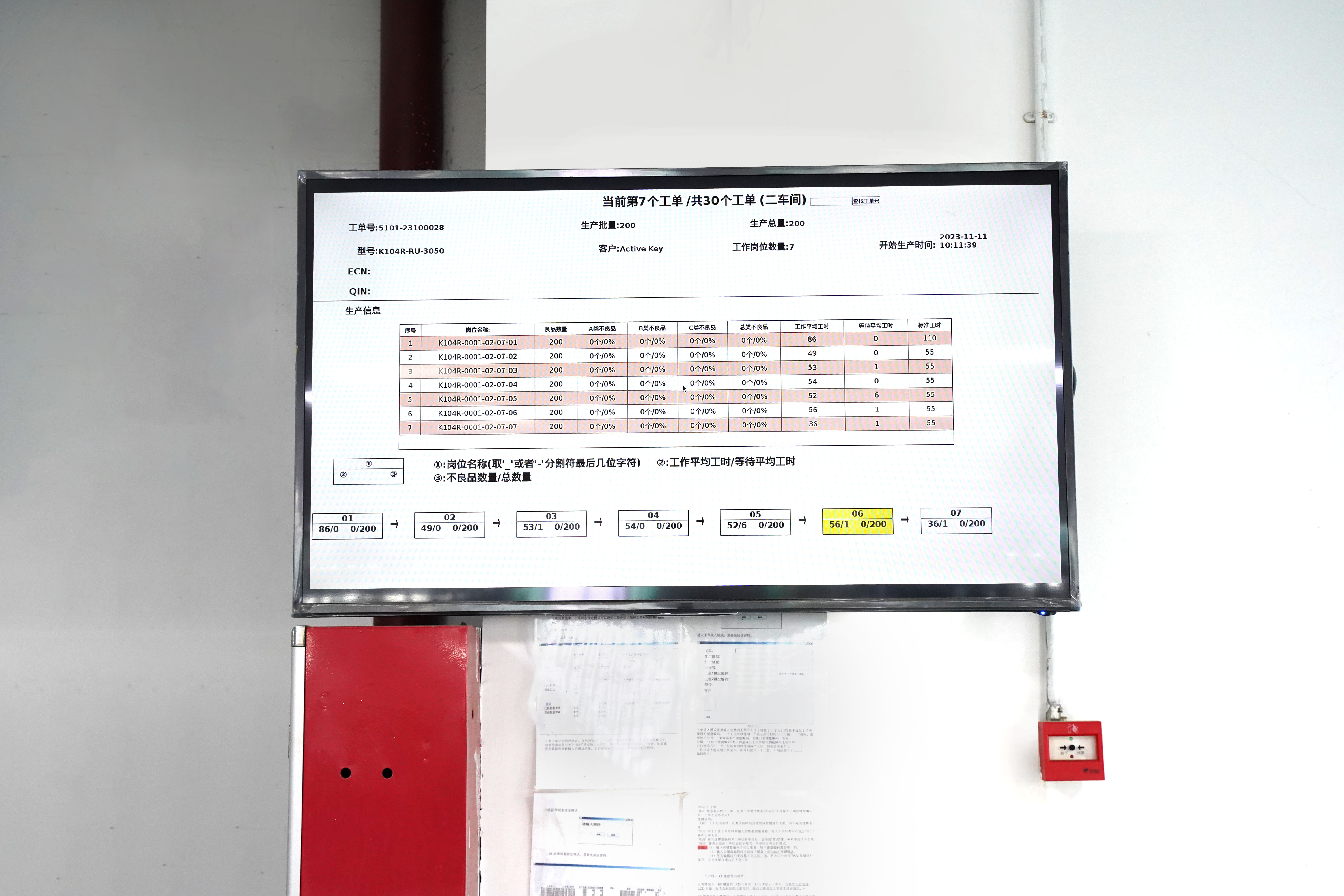

Process performance monitoring - If the job completion average time exceeds the threshold, the corresponding job number on the Kanban will turn yellow so as to remind the line manager to adjust the job station or adjust the whole process flow so as improve the working efficiency.

-

Job control improvement - Managers can use their mobile phones to scan the QR code on the smart terminal screen to enter the job control of the workstation, where they can change the worker, add precaution pictures, add defective product codes, etc., so that the workers can be alerted or trained immediately of the new precaution / change added.

Defective Product Management

- Defective product inspection - Defective products on the production line are transferred to the repairing station. The repair worker can retrieve work order information and fault symptoms based on barcodes of the defective products.

- Repair - The repair worker inspects and fixes or replaces the defective components on the defective products.

- Upload report - After the product is fixed, the repair worker enters the repairing report, set the product status code to “Repaired”, and upload the report.

- Product return to work station - The repaired products are returned to the original job station and redo all the checking and assemble.. If the repaired products are returned to the wrong job station, the system will also identify and prompt for the wrong placement.

Real Time Production Information

- Production Managers can monitor the real-time information of each production line at any time on the large kanban of each workshop or from internal smart production system installed on the production LAN. The real time information includes the number of work orders, working hours, working efficiency, production failure rates of each process.

Heng Yu's smart production system is designed to provide much more useful information to the production line managers and their workers. The system allows the production to provide real time and on the job training to the workers while monitoring their working performance. Production managers can then adjust the production process and control promptly, rather than doing the review after the production is done.